| Sr. No | Maker | X Travel | Y Travel | Z Travel | No of Machine |

|---|---|---|---|---|---|

| 1 | BFW BMV 60-1060 | 1060 mm | 600 mm | 600 mm | 1 |

| 2 | JYOTI-850 | 800 mm | 500 mm | 500 mm | 1 |

| 3 | ACE-MCV450 | 800 mm | 450 mm | 500 mm | 1 |

| 4 | ACE-MCV450 2-PALLET | 800 mm | 510 mm | 500 mm | 1 |

We specialize in the development of components as per customer samples, drawings, and technical specifications, ensuring precise translation of requirements into manufacturable products.

Ascot Technotech has in-house design and process engineering capabilities, enabling us to design both the product and the manufacturing process for optimum performance and efficiency.

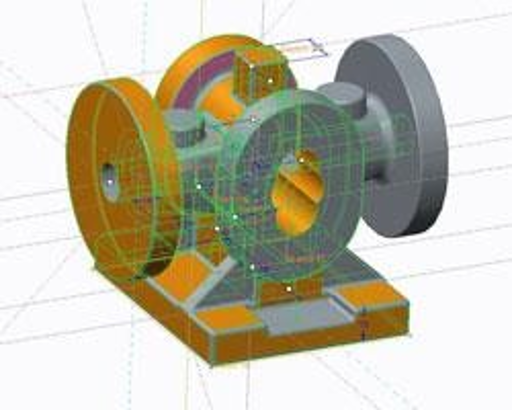

Advanced CAD and CAM tools are used for accurate design, simulation, and precision machining, ensuring consistency and repeatability.

In close consultation with our customers, we optimize and redesign components or processes to enhance product quality, improve manufacturability, and deliver cost-effective solutions without compromising performance.

Ascot Technotech operates a well-equipped machining facility featuring advanced CNC and VMC machines with 4th-axis capability, supported by post-machining facilities such as hydro testing, wire cutting, laser marking, EDM, and dynamic balancing. This comprehensive setup enables us to manufacture precision components with high accuracy, consistency, and production flexibility.

Our enhanced inspection and quality control facility is equipped with a CMM (Coordinate Measuring Machine) and a comprehensive range of measuring instruments, including height gauges, micrometres, bore gauges, Roughness Tester, vernier calipers, plug gauges, thread gauges, ring gauges, and slip gauges. These tools ensure strict dimensional control and compliance with customer and international quality standards.